- Home

- News

- News Category

- How a Metal CNC Lathe Machine Works: Key Functions, Capabilities, and Use Cases

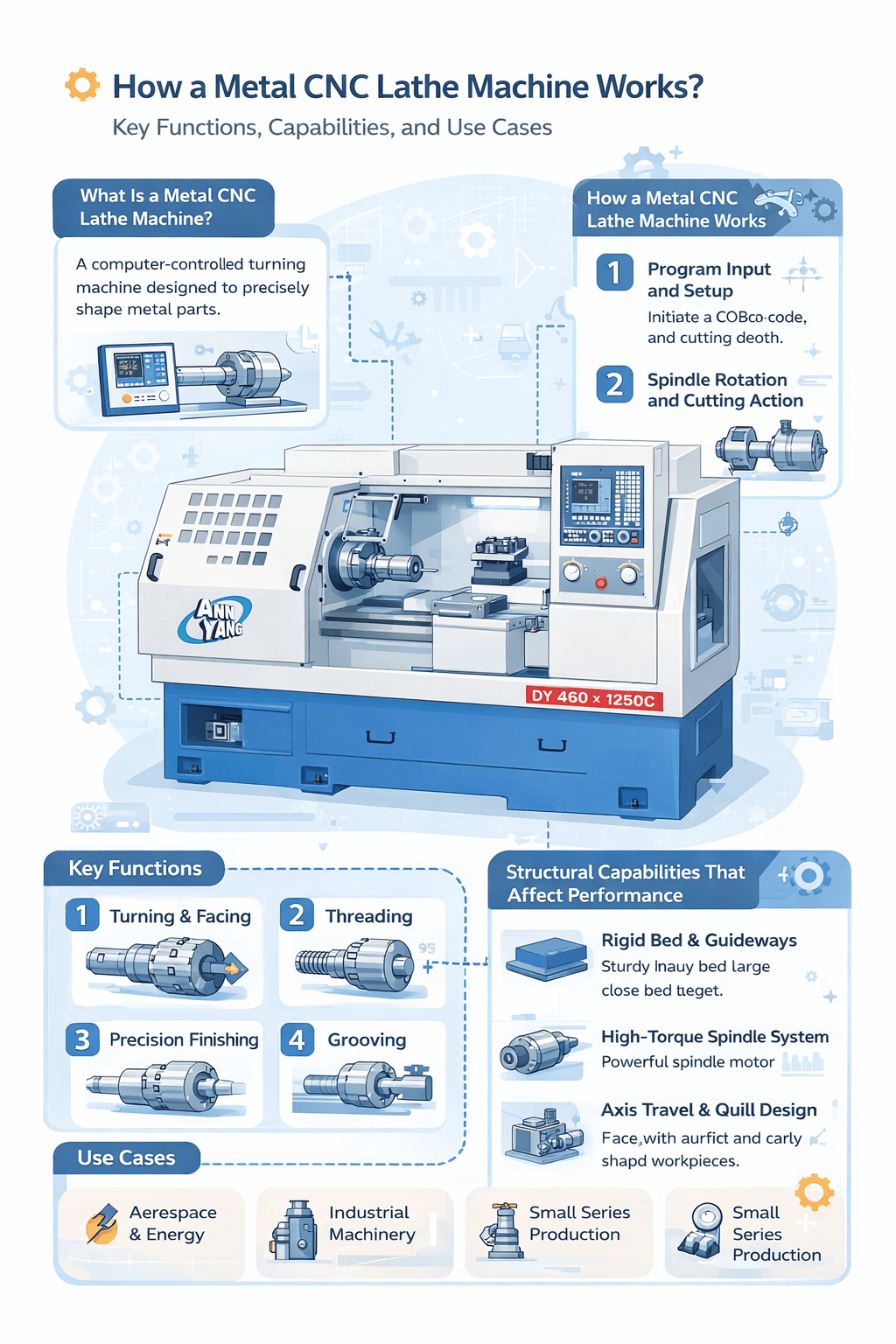

How a Metal CNC Lathe Machine Works: Key Functions, Capabilities, and Use Cases

Metal CNC lathe machine working principles matter to engineers, buyers, and manufacturers who need precision, repeatability, and stable production quality. From aerospace components to industrial machinery parts, CNC lathes help achieve tight tolerances while supporting efficient workflows.

In this guide, we explain how a metal CNC lathe machine works, outline its key functions and performance capabilities, and share real-world use cases for modern manufacturing decision-makers.

What Is a Metal CNC Lathe Machine?

A metal CNC lathe machine is a computer-controlled turning machine designed to shape metal workpieces by rotating them against precision cutting tools. Compared with manual lathes, CNC lathes follow programmed instructions (G-code) that deliver consistent, repeatable results with reduced operator dependency.

Metal CNC lathes are commonly used to produce shafts, bushings, flanges, threaded parts, and other cylindrical components across many industries.

How a Metal CNC Lathe Machine Works

Understanding metal CNC lathe machine working principles starts with three core elements: the workpiece, the cutting tool, and the CNC control system. The controller coordinates spindle rotation and tool movement to remove material precisely and efficiently.

- Program Input and Setup

The machining process begins with a CNC program that defines spindle speed, feed rate, tool path, and depth of cut. The operator loads the program into the controller and secures the metal workpiece using a chuck or centers. - Spindle Rotation and Cutting Action

During turning, the spindle rotates the workpiece at controlled RPM, while the cutting tool advances along the machine axes (typically X and Z). This synchronized motion removes material to reach the required diameter, geometry, and surface finish. - Automated Tool Control

Modern CNC lathes can automate tool changes, maintain accurate tool offsets, and execute multi-step operations without repeated manual adjustments. This reduces human error and improves productivity, especially for small to medium batch manufacturing.

Key Functions of a Metal CNC Lathe Machine

- Turning and Facing

Core operations include external turning, internal boring, and facing. These functions form the foundation for producing a wide range of cylindrical and rotational parts. - Threading and Grooving

CNC-controlled threading delivers consistent pitch, depth, and profile accuracy. Grooving functions support sealing surfaces, snap-ring seats, and mechanical interfaces required in industrial components. - Precision Finishing

By controlling feed, speed, and tool paths, CNC lathes deliver stable surface finishes and predictable dimensional accuracy across materials such as stainless steel, carbon steel, and alloy steel.

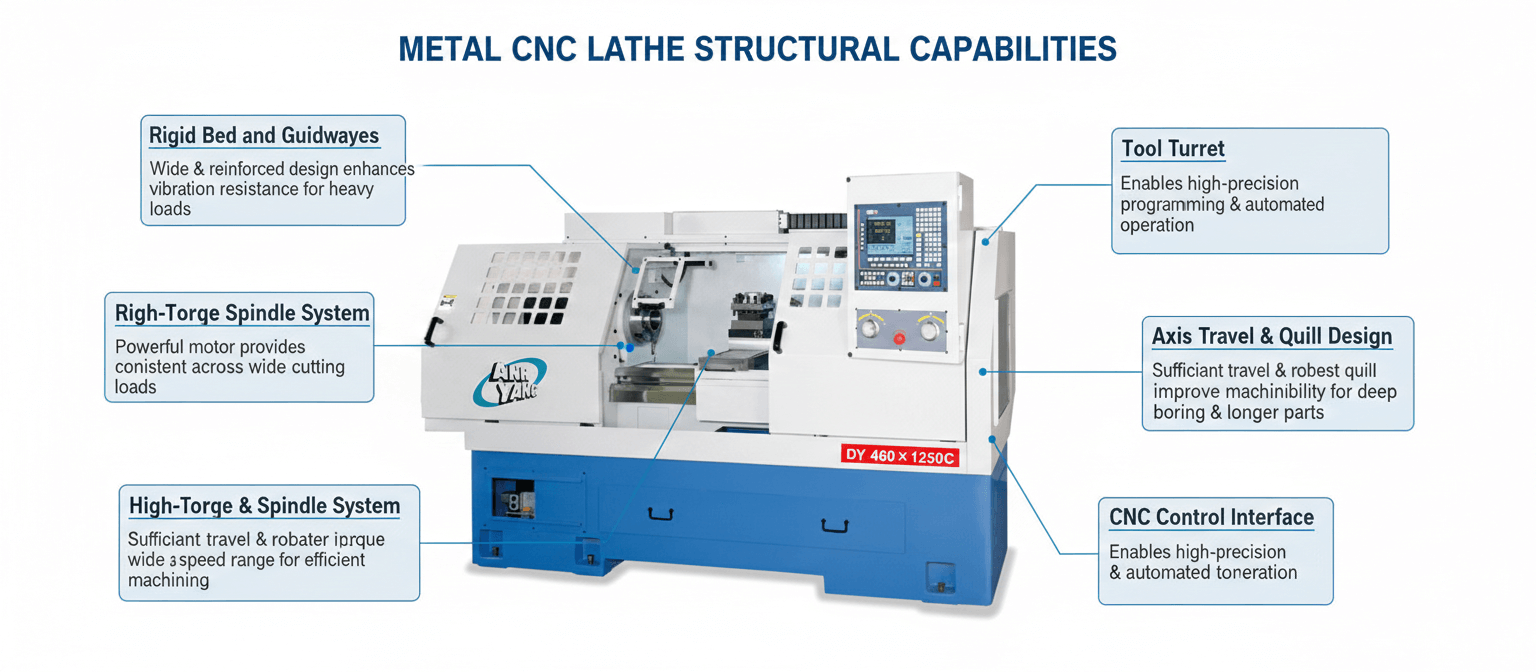

Structural Capabilities That Affect Performance

When evaluating CNC lathe capabilities, structural design and rigidity directly influence vibration control, precision stability, and long-term performance.

- Rigid Bed and Guideways

A reinforced lathe bed and robust guideway design improve cutting stability under load. Increased rigidity helps maintain accuracy during heavy-duty operations and supports consistent tolerances over time. - High-Torque Spindle System

Spindle power and torque delivery affect cutting efficiency, cycle time, and surface finish. A high-torque spindle enables smooth machining across a wide speed range for varied part sizes and materials. - Axis Travel and Quill Design

Adequate axis travel and strong quill design expand machining flexibility, supporting deeper boring and longer part processing for industrial workloads.

Typical Use Cases for Metal CNC Lathe Machines

- Aerospace and Energy

Aerospace and energy industries require tight tolerances and stable quality for turned components such as shafts, connectors, and structural parts. CNC turning ensures repeatable accuracy for critical production standards. - Industrial Machinery Manufacturing

CNC lathes are widely used for manufacturing transmission parts, hydraulic components, and custom mechanical assemblies that demand durability and precision. - Small Series and Customized Production

For small batch orders and frequent design changes, CNC lathes deliver faster changeovers and reliable repeatability without heavy tooling investment, supporting agile production and export-oriented manufacturing.

Optional Upgrades and Automation Solutions

To meet evolving production requirements, CNC lathes may support optional upgrades such as automatic loading and unloading systems, user-friendly controllers, and heavy-duty configurations for larger workpieces.

- Auto loading / unloading robots for higher throughput

- Advanced CNC control systems for easier operation and faster setup

- Heavy-duty options for large-diameter or long workpieces

Why Understanding CNC Lathe Working Principles Matters

For engineers and procurement teams, understanding how a metal CNC lathe machine works helps evaluate whether a machine can meet quality targets, throughput goals, and long-term ROI expectations. Rigidity, control accuracy, and functional flexibility are key factors that affect manufacturing competitiveness.

Conclusion

A metal CNC lathe machine is a core solution for modern precision manufacturing. With computer-controlled motion, stable mechanical structures, and versatile turning functions, CNC lathes deliver consistent results across aerospace, energy, and industrial machinery applications.

By understanding metal CNC lathe machine working principles, key functions, performance capabilities, and real-world use cases, manufacturers can make informed investments and build sustainable, high-quality production systems.

FAQ: Metal CNC Lathe Machine Working

What is the working principle of a metal CNC lathe machine?

A metal CNC lathe rotates a workpiece via the spindle while the CNC controller moves cutting tools along precise axes to remove material. The process is governed by a CNC program that controls speed, feed, and tool paths for repeatable machining accuracy.

What parts can a CNC lathe machine produce?

Common parts include shafts, bushings, flanges, threaded components, couplings, and other cylindrical or rotational parts used in industrial machinery, energy systems, and aerospace applications.

What industries use metal CNC lathes the most?

Metal CNC lathes are widely used in aerospace, energy, industrial machinery, automotive supply chains, and manufacturing environments that require precision and repeatability.